The T-62 medium tank, known under the factory product code of Object 166, formally entered service in the Soviet Army on the 12th of August 1961. The tank was designed by the OKB-520 design bureau headed by Leonid Kartsev and built at the No. 183 factory at Nizhny Tagil (now Uralvagonzavod). The tank was accepted into service as an interim countermeasure against the new American M60 tank. The M60 itself was not the tank most desired by the U.S Army as it was merely an interim solution to the slow progress of the T95 tank programme that went ahead on the basis of new information regarding the capabilities of the T-54, and it was perceived to be a dangerous new threat with overmatching capabilities by Soviet intelligence chiefly due to its 105mm M68 gun. Interestingly enough, the adoption of the 105mm L7 on Centurion tanks some years prior to the appearance of the M60 was not considered a significant development by the Soviet high command due to the small military presence of the British Army relative to the U.S Army and the Bundeswehr, which was supplied with American tanks. The priority was thus focused on assessing the American tank threat above all other potential adversaries.

Although the T-62 was considered a new tank as it was taken into service, most of its parts were standardized with the T-55 and crew training for these two tanks were so similar that practically no transitional training was required for a T-55 crew member to transfer to a T-62. In this respect, the relationship between the T-62 and the T-55 was quite similar to the relationship between the M48 Patton and the M60(A1).

To counter the M60, the main developmental effort was directed towards putting a new tank with the powerful 100mm T-12 smoothbore anti-tank gun in service. The 115mm U-5TS gun of the T-62 was created as a result of this effort, as it was able to to provide a level of armour-piercing performance matching the 100mm T-12 gun (in actuality, exceeding it) while avoiding the issue of excessive cartridge length. Were it not for the extreme length of its cartridges, the T-12 gun could have been fitted in a medium tank after modifications to the recoil system.

The first prototypes were built in 1960 for factory testing, and in the following year, a batch of 25 tanks was manufactured for troop trials. Mass production began on the 1st of July 1962 and lasted until 1973, when it was replaced by the T-72. The T-62 began active service extremely swiftly; by 1963 it was already operational in the Group of Soviet Forces in Germany (GSFG) and it began supplanting the T-54 and T-55 in the Soviet Army. Production of the T-62 accelerated extremely rapidly, with 270 tanks produced in 1962 alone despite the late start in July as the first half of the year was occupied by extensive retooling efforts in preparation for mass production. This included the retooling of the automated welding processing line and the replacement of the rotary machines for turret ring production, among other things.

According to data published in the book "Уральский вагоностроительный завод. 80 лет", already by 1965, the total number of T-62 tanks delivered to the Soviet Army was 4,475 tanks, exceeding the cumulative total of 3,721 M60 and M60A1 tanks delivered to the U.S Army and the difference continued to grow over the years owing to the fact that the delivery rate of T-62 tanks averaged 1.5 thousand units per year whereas the annual production rate of M60A1 tanks (the M60 was discontinued in 1963) never exceeded 300 tanks until 1975. By 1973, the T-62 had almost entirely replaced the T-10M heavy tank and it had largely supplanted the T-54/55 in the GSFG, but even so, it was not considered a main battle tank.

However, main battle tank or not, available information shows that the T-62 not only managed to achieve parity with NATO main battle tanks like the M60A1, Chieftain and Leopard 1 but could even hold a minor advantage in several critical areas which enabled it to gain an advantage in kill probability over its adversaries.

However, main battle tank or not, available information shows that the T-62 not only managed to achieve parity with NATO main battle tanks like the M60A1, Chieftain and Leopard 1 but could even hold a minor advantage in several critical areas which enabled it to gain an advantage in kill probability over its adversaries.

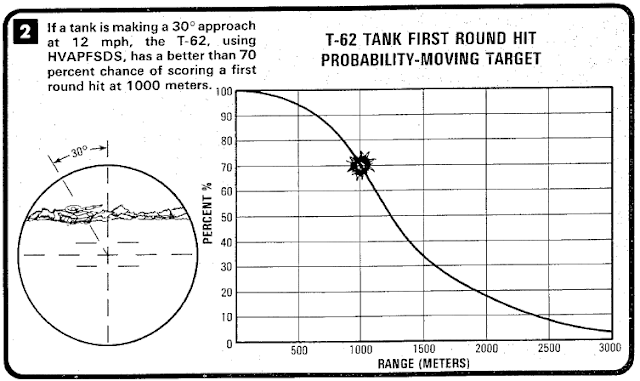

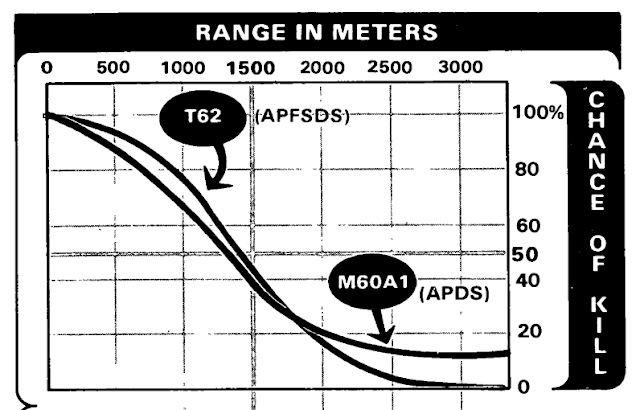

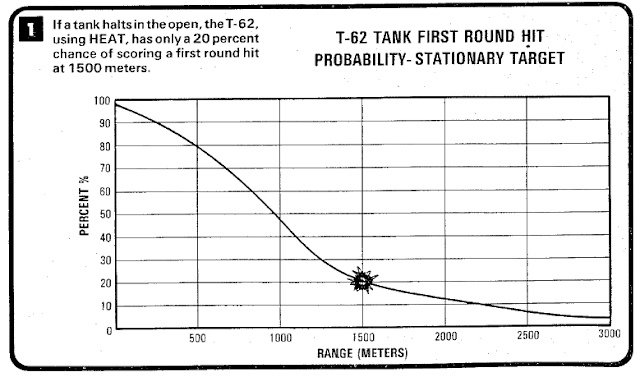

Bearing in mind that the T-62 was an unpretentious tank by design, the high velocity APFSDS ammunition fired from its smoothbore 115mm gun allowed it to achieve a level of anti-tank performance that outmatched the M60A1 despite the absence of an optical rangefinder and a ballistic computer as found on American tanks - in the 1977 edition of the field manual FM71-2, it is stated that the T-62 holds a 5-10% advantage of killing an M60A1 with the first shot at a range of between 600 to 1,400 meters with its APFSDS round (3BM4) compared to the M60A1's chance of killing a T-62 with its APDS round (M728) on the first shot. The M60A1 gained the upper hand at distances exceeding 2,000 meters, but this mattered little in a major European war given that the maximum expected tank combat distance did not exceed 1,500 meters in Central and Western Europe. In Germany, during the course of the Hunfeld II study that was carried out in the early 1970's in the Hünfeld region of Fulda, Germany, it was found that the average engagement range for M60A1 tanks was just 1,130 meters. At the infamous Fulda Gap itself, the maximum expected combat distance was just 800 meters.

In terms of mobility, the T-62 still held its own against the new generation of NATO main battle tanks partly because the M60A1 and Chieftain were both only slightly more mobile than its medium tank predecessors or not more mobile at all, while the Leopard 1 sacrificed a large amount of armour to achieve its mobility advantage. This sacrifice came at the cost of a higher probability of destruction - according to West German calculations derived from examinations of captured T-62 tanks delivered from Israel after the 1973 war, the Leopard 1 could achieve a slightly higher probability of a hit with the first shot against a T-62 (57% vs 52% at 1.5 km) but it was considered to be outgunned because the APFSDS round fired from the T-62 greatly overmatched the Leopard's armour and gave the T-62 the advantage of a higher probability of scoring a kill with the first shot. The Leopard 1 also lacked a gun stabilizer, so it could not leverage its superior mobility to increase its survivability by firing on the move. On the other hand, the T-62 had a good stabilizer system and it could fire on the move or quickly open fire on a short halt at ranges of 1.0 to 1.5 kilometers.

The tanks that were modernized to the "M" standard officially entered service in 1983. According to the scope of the modernization programme, a total of 2,985 T-55AM and T-62M tanks would be upgraded from 1981 to 1985. Of that number, there would be 2,200 upgraded T-55 tanks and 785 upgraded T-62 tanks. The first ten tanks upgraded to the T-62M standard were delivered in 1981, and in 1982, forty tanks were delivered. In 1983, the model was officially accepted into service and fifty tanks were delivered in the same year. In 1984, the number of deliveries doubled to a hundred tanks, and in 1985, the full preparation of the necessary facilities and equipment enabled a whopping six hundred tanks to be delivered, thus fulfilling the objective of the programme. The production of T-72 tanks also peaked in 1985, coinciding with the entry of the T-72B into the service of the Soviet Army. All together, the tank fleet of the front line forces of the Soviet Army was successfully modernized.

In terms of mobility, the T-62 still held its own against the new generation of NATO main battle tanks partly because the M60A1 and Chieftain were both only slightly more mobile than its medium tank predecessors or not more mobile at all, while the Leopard 1 sacrificed a large amount of armour to achieve its mobility advantage. This sacrifice came at the cost of a higher probability of destruction - according to West German calculations derived from examinations of captured T-62 tanks delivered from Israel after the 1973 war, the Leopard 1 could achieve a slightly higher probability of a hit with the first shot against a T-62 (57% vs 52% at 1.5 km) but it was considered to be outgunned because the APFSDS round fired from the T-62 greatly overmatched the Leopard's armour and gave the T-62 the advantage of a higher probability of scoring a kill with the first shot. The Leopard 1 also lacked a gun stabilizer, so it could not leverage its superior mobility to increase its survivability by firing on the move. On the other hand, the T-62 had a good stabilizer system and it could fire on the move or quickly open fire on a short halt at ranges of 1.0 to 1.5 kilometers.

All taken together, the T-62 was quite a formidable fighter on its own merits, not to mention that it was largely a necessity because it brought the necessary firepower to counter the M60A1 and Chieftain, but its attractiveness was further augmented by the fact that it was cheap (only 15% more expensive than a T-55), was highly cost-efficient, easy to produce in great quantities, simple to operate, and easy to train on due to its very high degree of commonality with the T-54 and T-55, whereas the NATO main battle tanks of the 1960's were expensive and complex - and in the case of the Chieftain, very troublesome to maintain - yet failed to bring a corresponding qualitative advantage over their Soviet counterpart.

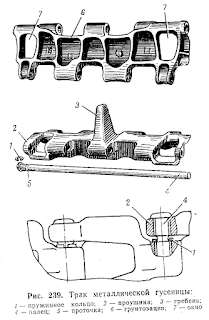

A decade after it entered service, the T-62 was replaced by the T-64 and T-72 main battle tanks and it slowly began to be shifted to a secondary role. However, it was clear that the total replacement of the T-62 (and the T-54 series) would not be quick due to the immense size of the Soviet Army. As such, the T-62 continued to serve until the dissolution of the USSR. It remained a valuable wartime asset throughout the 1970's partly thanks to the solidity of its basic design, but it was enhanced by a number of low-level upgrades. The cost of such upgrades was low and they were performed during routine repairs at a predetermined point in the life cycle of each tank. Such upgrades included the refitting of new RMSh tracks and the addition of a KDT-1 laser rangefinder.

A decade after it entered service, the T-62 was replaced by the T-64 and T-72 main battle tanks and it slowly began to be shifted to a secondary role. However, it was clear that the total replacement of the T-62 (and the T-54 series) would not be quick due to the immense size of the Soviet Army. As such, the T-62 continued to serve until the dissolution of the USSR. It remained a valuable wartime asset throughout the 1970's partly thanks to the solidity of its basic design, but it was enhanced by a number of low-level upgrades. The cost of such upgrades was low and they were performed during routine repairs at a predetermined point in the life cycle of each tank. Such upgrades included the refitting of new RMSh tracks and the addition of a KDT-1 laser rangefinder.

With a total of around 14,000 tanks produced for the Soviet Army, it was only natural that the T-62 formed a major part of its arsenal even by the 1980's. However, by the end of the 1970's, a new generation of NATO tanks had appeared and a significant portion of the tank fleets of the major NATO military powers had undergone upgrades of some kind. Despite a constant escalation in the production rate of the newest main battle tanks such as the T-64B and T-72A, more than a quarter of the tanks in active service were still T-62s of various types. In order to fill the gap, a comprehensive modernization package developed at Nizhny Tagil was approved in 1981 and a programme was initiated to bring the T-62M and its sister, the T-55(A)M, into service. This upgrade focused on improving the armour protection and the fire control system to the standards of a baseline Soviet main battle tank from the early 1970's, equivalent to a basic T-64A or a T-72 "Ural", while improvements to the suspension and powertrain allowed the mobility characteristics to be remain positive. Firepower was improved thanks to new 115mm APFSDS ammunition and "Sheksna" gun-launched ATGMs, which a large portion of the modernized tanks could fire. Overall, these improvements made the T-62M a much more credible threat in the modern battlefield of the time. A large number of variants were derived from the basic "M" model of the modernization package.

The tanks that were modernized to the "M" standard officially entered service in 1983. According to the scope of the modernization programme, a total of 2,985 T-55AM and T-62M tanks would be upgraded from 1981 to 1985. Of that number, there would be 2,200 upgraded T-55 tanks and 785 upgraded T-62 tanks. The first ten tanks upgraded to the T-62M standard were delivered in 1981, and in 1982, forty tanks were delivered. In 1983, the model was officially accepted into service and fifty tanks were delivered in the same year. In 1984, the number of deliveries doubled to a hundred tanks, and in 1985, the full preparation of the necessary facilities and equipment enabled a whopping six hundred tanks to be delivered, thus fulfilling the objective of the programme. The production of T-72 tanks also peaked in 1985, coinciding with the entry of the T-72B into the service of the Soviet Army. All together, the tank fleet of the front line forces of the Soviet Army was successfully modernized.

Moreover, the number of tanks that were upgraded along the lines of the T-62M were actually much higher as a result of the war in Afghanistan. The relatively large quantity of basic T-54/55 and T-62 tanks present in the theater of operations found themselves vulnerable to handheld anti-tank weapons elements such as captured RPG-7s, so some troops took the additional composite armour from the T-62M modernization package and fitted them to their own tanks at local depots without incorporating the other components of the package.

Slat armour screens - which were not a part of the original T-62M modernization package - also made their debut in Afghanistan. Such screens were installed at local bases and were highly valued because of the proliferation of handheld grenade launchers among Mujahideen fighters.

The details of such tanks will be explored later in this article.

Today, the T-62 is perhaps the least remembered among large number of tanks deployed by the Soviet Union during the Cold War. Its predecessor, the T-54/55, is known for being the so-called "Kalashnikov of tanks", having seen action in virtually every major military conflict on the planet during the past half century. Its successor, the T-72, has a similar level of fame for having participated in almost as many conflicts and in being the most mass-produced main battle tank. The T-62, on the other hand, lies in an indeterminate gray area. It is usually sidelined as an oddity, sometimes accused of being a failure, and sometimes (bizarrely) criticized for having a smoothbore gun. In the West, the T-62 is best remembered by those who served in NATO armies in the 1973-1980 time frame, especially those stationed in West Germany. Publicly available TRADOC documents and training films show that the U.S Army emphasized the T-62 as a foil to their own M60A1, which was apt considering that that was the political motivation behind the creation of the T-62. When more information on the T-64 and T-72 became available in the early to mid 1980's, all attention was shifted towards these two models and lesson plans focused on training soldiers to defeat an enemy tank that had composite armour.

Tactically speaking, there was practically no difference between it and its predecessor the T-55 in the mobility and armour protection departments, and the T-62 also shared most of its internal equipment with the T-55, thus simplifying both production and logistics to a certain extent. Even many of the newer devices were functionally similar, making the transition from a T-54 or T-55 to the T-62 wonderfully seamless for the crew. In fact, it is stated in a 1981 Soviet essay titled "Из Опыта Совершенствования Основных Танков В Ходе Серийного Производства" that 65% of the parts and assemblies in the T-62 were standardized with the T-55 tank. Most interestingly, the transmission, chassis, engine assembly, viewing devices and communication systems were completely interchangeable between the two contemporary tanks. Operationally, this made it extremely simple to supply spare parts and carry out repairs in the field. The non-interchangeable components such as the turret and hull are irrelevant as these items would never require a replacement. Rather, if a tank were knocked out by having its armour breached, it is much more likely to be salvaged for spare parts to support other tanks rather than be repaired, as that is much more expedient in actual wartime conditions.

That said, the high degree of commonality was not entirely positive, because this meant that the T-62 was only an evolutionary improvement that still remained at the same technological level as its predecessors. This affected its export success as clients were not too keen on adopting a new tank that only surpassed the T-54 in terms of firepower without a clear advantage in armour protection and no difference in mobility. It was generally considered to be no more than a stopgap solution until a new and radically superior tank arrived on the scene, but despite this, the T-62 was also one of the most powerful medium tanks fielded by the Soviet Army, the other being the T-64 (Object 432) that had a D-68 gun that fired the same ammunition as the U-5TS but in a two-piece form. The T-62 was also one of the last medium tanks fielded by the Soviet Army, as this class of tank was later replaced by the next generation of tanks known as the main battle tank. Although the replacement of medium tanks with a bona fide main battle tank did not occur until the T-64A entered service in 1967, the rate of progress in the advancement of tank technology in the USSR was still quite reasonable if compared to the state of affairs in the United States where total stagnation could be found with the M60A1 (itself an evolutionary step with only a marginally higher combat effectiveness than its predecessor the M48 owing to the failure of the siliceous core composite armour project) being the de facto main battle tank for two decades until the M1 Abrams supplanted it in the early 1980's.

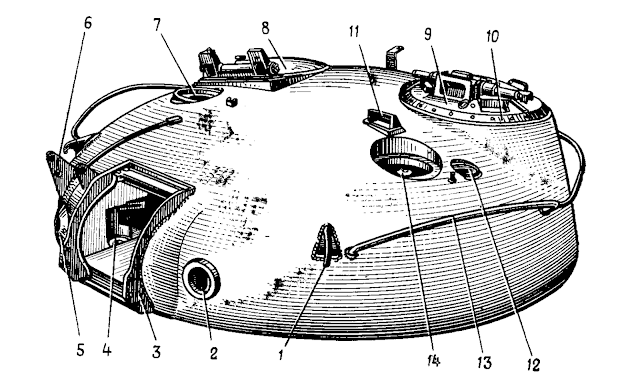

Being a mere evolutionary stepping stone, we can observe the way Soviet school of thought on mechanized warfare evolved with it. In the early 60's, tank riding infantry was still considered a core part of mechanized warfare. The armoured APC had arrived on the scene in the form of the wheeled BTR-152 and tracked BTR-50, but infantry were sometimes obliged to move and fight as one with a tank as they could effectively provide protection from enemy anti-tank teams equipped with grenade launchers, and so to that end, the T-62 had handrails over the circumference of the turret for tank riders to hold on to. When the BMP-1 was introduced in 1966, it drove a major revision of contemporary tank tactics, and the shift in paradigm can be very well seen in the T-62's successors. The T-64A did not have any handrails, nor did the T-72, and the T-62M introduced in the 80's abolished them too.

The changes to the T-62 dutifully followed international trends as well, most notably the global shift to jet power in the aviation industry. Too fast to be harmed by machine gun fire, the ground attack jet rendered the normally obligatory 12.7mm anti-aircraft machine gun obsolete. During the late 1950's and early 1960's, anti-aircraft machine guns were thus omitted from medium tanks but remained on heavy tanks like the T-10M, partly because the KPVT on the T-10M offered more firepower than the smaller caliber DShKM on medium tanks. Even the usefulness of a 12.7mm machine gun on ground targets was not persuasive enough to justify the retention of anti-aircraft machine guns to Soviet specialists at the GBTU (Main Directorate of Armoured Forces). The T-55, T-55A and T-62 were all affected by this new policy. The heavy use of helicopters for fire support and landing missions during the American war in Vietnam created a need for tanks to be armed with a large caliber anti-aircraft machine gun, and this was further emphasized by the appearance of dedicated attack helicopters or gunships like the AH-1 "Huey Cobra". The first T-62 tanks armed with a DShKM in an anti-aircraft mount appeared in 1969, and this modification became standard for new-production tanks beginning in May 1970. Older tanks were also retrofitted at the factory when they were brought in for their scheduled overhauls.

The first pre-production models of the T-62 appeared in 1961. In the Soviet Union, the T-62 was mass-produced from 1962 to 1975, making it the direct contemporary of NATO tanks like the M60A1, Leopard 1 and Chieftain which appeared in 1962, 1965 and 1966 respectively. After 1975, all "new" T-62s are actually simply upgraded, modified, or otherwise overhauled versions from the original production run. By then, production at the No. 183 factory had irreversibly shifted to T-72 production.

Like the M60A1, Leopard 1 and Chieftain, the T-62 was a completely different tank than its predecessor, but unlike these three foreign tanks, it did not represent a major change in mobility or protection. Technically speaking, the only difference was in its firepower. Nevertheless, the inherently good tactical-technical characteristics of the basic T-54 were so good and the original design was so solid that the T-62 could still be considered an equal among these main battle tanks.

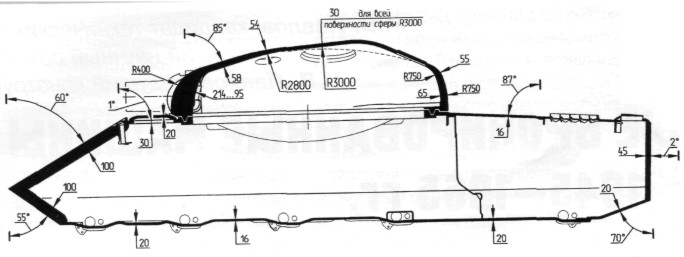

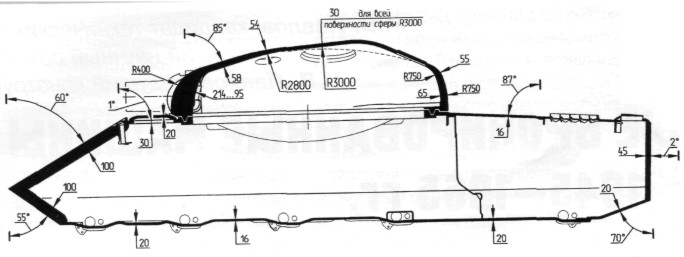

The topic of differentiating the T-62 from the T-54/55 can be addressed quite easily as there were a myriad of differences that distinguished the T-62 from the T-54. The enlarged turret, now completely round, is the most major external difference between the two tanks, but the hull was also changed. Internally, the hull has a width of 1,850mm as shown in the drawing below, taken from the book "Боевые Машины Уралвагонзавода: Танки 1960-х" by Uralvagonzavod corporation. This is wider than the AMX-30 (1,780mm) but narrower than the Leopard 1 (1,980mm), both tanks of comparable silhouette size. The length of the fighting compartment increased by 386mm while the length of the engine compartment increased by 84mm. In total, the length of the hull increased by 470mm. The width across the hull extensions for the turret ring is not given in the book, but would be 2,760mm according to a technical description.

The height of the hull was slightly increased from the T-55 as well. At the center of the hull where the fighting compartment is located, the internal height increased from 937mm to 1006mm. At the front of the hull, the internal height increased from 927mm to 939mm. At the fighting compartment, the useful internal height is just over 950mm due to the need for floor panels atop the torsion bars of the suspension.

The widened turret ring did not directly affect the width of the hull, but the length of the fighting compartment had to be increased by a small amount (386mm) in order to accommodate its increased diameter. The arrangement of the roadwheels and the torsion bar suspension was also revised in accordance with the redistribution of weight towards the nose of the hull, thus removing the distinctive gap between the first and second roadwheels on the T-54 and T-55 that is often used as an identification feature. Instead, the T-62 suspension has its three front roadwheels densely packed together, with larger gaps between the last two roadwheels. The combat weight of the tank was increased by one ton to 37 tons, but of this weight, less than 400 kg can be attributed to the weight difference between the 115mm U-5TS and the D10-T2S. The remainder is from the new hull and turret. Contrary to expectations, the T-62 was actually slightly lighter than the T-55A, which weighed 37.5 tons combat loaded.

However, that was not the entire extent of the changes made to the hull and chassis. Compared to the T-54/55, the maximum height of the hull was increased from 977mm to 1,036mm and the maximum internal height of the fighting compartment (from the rotating turret floor to the turret ceiling) went up very slightly from 1,600mm to 1,610mm. Due to the mildly sloping roof of the hull, the actual internal height differs at varying points across its length. Moreover, the suspension of the T-62 was fundamentally identical to the T-54 suspension, but it incorporated small improvements such as an increased ground clearance of 471.5mm instead of 440mm and it provided a somewhat smoother ride. Externally, at first glance, it seems that the T-62 is both wider and taller the T-54/55 by a few inches but surprisingly, the height of the T-62 up to its turret roof almost did not change at all compared to the T-54 - it increased only negligibly from 2,235mm to 2,248mm. Like the T-54, the total height of the tank up to the top of the commander's cupola is 2,400mm.

The internal volume of a T-62 was larger compared to a T-54 or T-55 chiefly due to the need to accommodate the bigger gun, but due to the increase in the turret ring diameter and the rearrangement of the internal equipment in the tank, it was possible to allocate more room to the crew. Although the T-62 superficially resembles the T-54 from many angles, the dome-shaped turret was larger and noticeably more spacious, even with the larger cannon. This can be largely attributed to the 2,245mm diameter turret ring, which was not only a big improvement over the 1,825mm ring of the T-54, but it was even quite cavernous compared to foreign tanks. The photo below, provided courtesy of Chris "Toadman" Hughes, shows a stripped-out T-62 hull.

The total internal volume of the T-54/55 is 11.4 cubic meters whereas the total internal volume of a T-62 is 12.5 cubic meters. Of that, the volume of the crew compartment is 8.05 cubic meters and 9.23 cubic meters for the T-54/55 and the T-62 respectively. After taking the internal equipment into consideration, the T-62 is the roomier of the two models by a small margin. In the third edition of the “Отечественные Бронированные Машины 1945–1965 ГГ.” series of articles authored by M.V Pavlov and I.V Pavlov, published in the July 2008 edition of the “Техника и вооружение” magazine, it is stated that the internal volume of the T-62 is 11.95 cubic meters, with 9.75 cubic meters from the hull and 2.2 cubic meters from the turret. For comparison, it is also stated that the T-55 has an internal volume of 11.1 cubic meters with 8.6 cubic meters from the hull and 2.5 cubic meters from the turret.

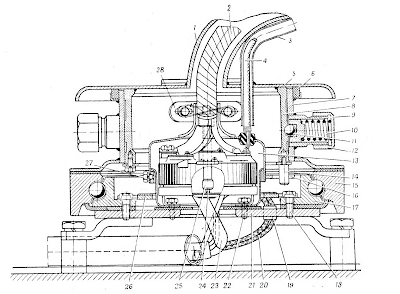

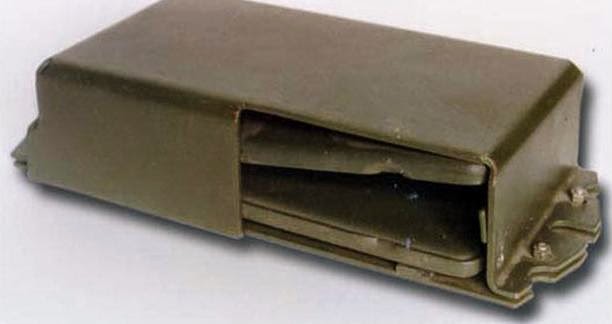

The ventilation exhaust fan can be turned on to draw air into the engine compartment via the crew compartment even if the ventilation blower is not used. In this case, air enters the crew compartment mainly via small gaps and through airways such as the signal pistol port in the commander's hatch. The location of the ventilation exhaust fan is shown in the drawing on the left below, marked (5), and the fan itself is shown on the right below. Heated air from the engine compartment does not permeate into the crew compartment through the ventilation exhaust duct even when the tank is idling because the exhaust fan ensures a constant air flow into the engine compartment.

For personal ventilation, the gunner, loader and driver were each provided with a DV-3 fan, as shown in the diagrams below. Only the commander lacked a fan, but considering that his seat is directly adjacent to the vent for the ventilation blower, there was probably no need for one. In the diagram on the left below (click to enlarge), the gunner's personal fan is marked (13) and the loader's personal fan is marked (20). In the diagram on the right below, the driver's personal fan is marked (44). The DV-3 is a simple 5.2W fan running on the 27 V electrical network of the tank. The commander does not have a personal fan, but he presumably does not need one, because the air outlet for the ventilator is just behind him. When not in use, the personal fans are folded away. The gunner's personal fan is behind the control handles to blow directly on the gunner's face, the loader's personal fan is on the turret ring next to his seat, and the driver's personal fan is next to the instrument panel, also aimed to blow directly on the driver's face. These fans are normally found to be missing in interior photos of existing tanks, probably because they have been stolen.

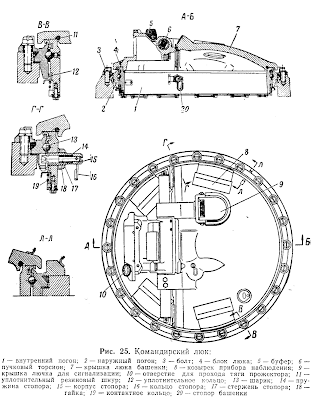

The commander is seated on the left side of the turret, directly behind the gunner. The commander is responsible for observing the tank's surroundings, searching for targets during combat, coordinating the crew or coordinating other tanks in the platoon or company, operating the R-113 radio transceiver set, and more. Unlike the rest of the dome-shaped turret of the T-62, the casting around the commander's station was shaped in such a way that it is devoid of any vertical sloping or curving whatsoever besides maintaining the circular shape of the turret. This was necessary to enable the commander's rotating cupola to be installed. This also meant that any debilitating effects of the shaping of turret (lack of headroom, for instance) do not directly apply to him as the cupola is raised slightly above the level of the turret roof and the hatch is dome-shaped to further increase the available headroom.

The commander's cupola superstructure is secured to the turret with screws rather than bolts like on the T-54, but a new bolted cupola superstructure was implemented in the T-62 obr. 1972 model. The cupola is mounted on a race ring. The fixed part constitutes just under half of the total size of the cupola, while the other half is occupied by the semicircular hatch. The hatch opens forward, which is quite convenient for when the commander wants to survey the landscape from outside - perhaps with a pair of binoculars - because the considerable thickness of the hatch makes it a bulletproof shield to protect the commander from sniper fire. The hatch has a thickness of 30mm and is curved.

The commander's seat is thickly padded and he has a backrest as well as a footrest. On his immediate left is the A-1 communications control box of the R-114 intercome system. It is the master control box, serving as a connector hub for all other control boxes at each crew station. It enables the commander to switch between the radio(s) and the intercom for his headset. There are a few metal loops for strapping on personal effects, his binoculars (in its pouch), his personal sidearm (in its holster), a documents case and anything else that might need to be secured. He also has access to the turret traverse lock. Underneath his seat on the hull floor is the tank's heater unit. The commander's two-liter aluminium bottle can be seen secured to its holder. Unlike in the T-54, the radio is installed below the turret ring and next to the gunner which frees up a lot of horizontal space for the commander above the level of his midriff at the expense of the gunner. On the T-54/55, there is a padded knee rest attached to the turret ring where the radio is located in the T-62. All of this can be seen in the two photos below.

The photo on the right (from Aleksey Kotov) shows the backrest of his seat and a few pieces of equipment. The turret traverse lock is just underneath the communications relay box. Besides these two components, there is very little else, and thanks to this, the commander has much more elbow room than a T-54/55 commander who is practically squeezed between the recoil guard on his right and the radio set on his left with enough space to only operate the radio and rotate the cupola with his hands on the handles. Overall, the amount of space for the T-62 commander is noticeably larger compared to the T-54/55 and it is entirely due to the very large turret diameter of 2,245mm. The screenshot below, taken from the video "The Beasts of Kabul: Inside the Afghan Army's Soviet Tanks" by the Stars and Stripes news organization, gives a relatively good perspective of this space.

Still, it's worth noting that in all of the images shown so far, the recoil guard between the commander and the U-5TS gun on his right has been removed. When installed, the recoil guard ensures that the commander's shoulder and arms do not enter the recoil path of the gun or get caught by any of its moving parts but allows him to see over its edge to communicate with the loader.

However, the larger turret ring diameter of the T-62 had much less effect on the space between the commander and gunner. This can be seen in the drawing above. The commander sits directly underneath his cupola and his footrest is just behind the gunner's seat, so unless the commander keeps his legs spread, his knees will be pushing into the gunner's back. The close proximity between the two crew members makes the internal climate hotter and more humid, contributing to the overall discomfort in summer. It may not be as bad in the winter, but still, this is not a positive trait of the tank. The small space between the two men is compounded by the fact that the crew isn't provided with directional ventilation devices such as blowers, fans or directed air vents, so it can get quite stuffy inside. However, both the commander and loader are seated next to the PAZ ventilator blower air outlet in the turret, which is installed underneath the spent shell casing ejection port at the back of the turret. Besides the roomy loader's station, the commander's seat is one of the better places to be in the very spartan T-62.

As with other Soviet tanks operated since 1954, the T-62 was fitted with an R-113 radio at the time it was introduced into service. The R-113 radio operates in the 20.00 to 22.375 MHz range and has a range of 10 to 20 km with its 4 m-long antenna. It could be tuned into 96 frequencies within the limits of its frequency range. The transmission power of the R-113 is 16 Watts. The narrow operating range of the radio is sufficient for tactical communications, but being so narrow, it is easy for NATO forces to earmark the 20-22.375 MHz frequency range as the known communications band of Soviet tanks and thereby jam the entire range, while NATO forces could still operate with minimal noise at completely different frequencies. The transceiver unit measures 428x239x222 mm, and the power supply unit is 210x166x220 mm.

The commander's primary periscope is either a TKN-2 or TKN-3 combined day-night periscope. It is boresighted to the main gun for a distance of no less than 1,000 meters, permitting accurate target designation. As befitting his tactical role, the commander's general visibility is facilitated by two TNPO-170 periscopes on either side of the primary surveillance periscope in the fixed forward half of the cupola, further augmented by two more periscopes embedded in the hatch, aimed to either side for additional situational awareness. Overall, this scheme could be considered more than adequate.

The active mode requires the use of the OU-3GK IR spotlight. Activating the OU-3GK is done the same way as with the TKN-2. With active infrared imaging, the commander can identify a tank at around 400 m or potentially more if the opposing side is also using IR spotlights, in which case, the TKN-3 can be set to the active mode but without turning on the IR spotlight. This way, the commander can see enemy tanks from many kilometers away at night, or at least three times further than the viewing range of the enemy tank relying on the spotlight. Without the infrared filter, the spotlight emits white light at 240 candlepower.

Like the TKN-2, the TKN-3 had separate optical channels for the night and day viewing modes. In the daytime channel, the two eyepieces lead to separate apertures to provide stereoscopic vision, thus providing depth perception. For the night channel, the optical channel from the two eyepieces were merged to view from a single aperture lens.

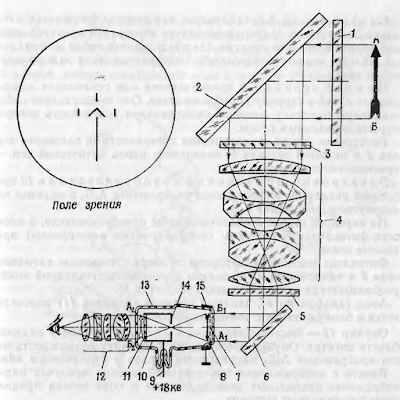

To switch between the day and night channels, the user simply rotates a dial on the right side of the periscope housing by 90 degrees. This flips an internal mirror by 90 degrees, thus changing the optical path between the night vision unit and the regular daytime optical channel. The diagram below shows the two choices. Diagram (a) on the left shows the path of the light from the aperture through the night vision system and into the eyepiece, while diagram (b) on the right shows the mirror flipped 90 degrees and the light from the aperture passing through the normal optical channel for daytime use.

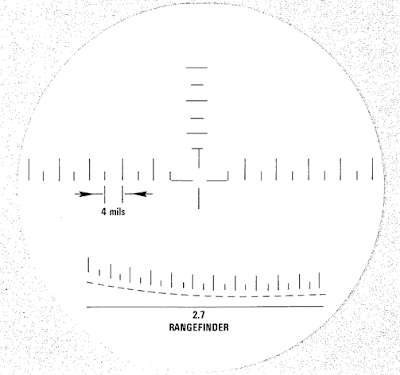

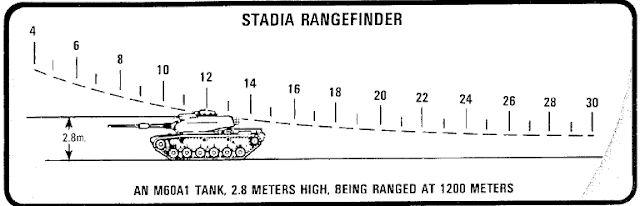

Rangefinding is accomplished through the use of a stadiametric scale calibrated for a target with a height of 2.7 m, which is the average height of the average NATO tank. The ranging error margin is negligible at distances of around a kilometer, but at distances exceeding approximately 1.6 km, it becomes difficult to accurately find the range of the target due to a multitude of factors, including weather conditions, limited magnification power, mirages (a big problem in deserts), and obstruction of parts of the tank (tall grass can hide the lower part of the hull). At long distances, contrast between the target tank and the background is also often very poor, since there is usually some modicum of camouflage to conceal the tank.

It is also possible to find the distance to the target tank by using the windage and elevation scales beside and above the central reticle in the TKN-3 viewfinder. Knowing the width of any Patton tank to be around 3.6 meters, the commander will know that the distance to the tank is exactly 900 meters if the tank can be bracketing it exactly between any two vertical lines on the windage scale (4 mils). If the commander sees a Patton tank presenting its profile, he can assume that its length is 7 meters, and he can place estimate the range to the tank by bracketing it between two of the long vertical lines on the windage scale (8 mils). If it fits perfectly, then the distance is just slightly under 900 meters, but can be rounded up to 900 meters with a negligible margin of error.

Like the TKN-2 and other previous binocular sights for the commander, the TKN-3 is not stabilized, making it exceedingly difficult to reliably identify enemy tanks or other vehicles at extended distances while the tank is travelling over rough terrain, let alone determine the range. On a related note, the lack of stabilization would have made it equally difficult to operate an optical coincidence or stereoscopic rangefinder, especially one with a high magnification. The M17 rangefinder used in M60A1, for example, would have been next to useless if the tank was in motion over rough terrain since the rangefinder had a fixed 10x magnification, so the oscillations from the movement of the tank could cause too much jolting for the commander to keep the target focused. This means that the rangefinder is only useful when the tank is static, which may have been perfectly fine for the M60A1 and its contemporaries if the situation consistently permitted the tank to remain static. The T-62, on the other hand, is an offensive tank designed to fulfill specific tactical-technical requirements while remaining affordable, and high-precision optical instruments did not necessarily fit into this plan.

Optical rangefinders were therefore understandably absent from Soviet medium and heavy tanks, but not from Soviet tank destroyers and assault guns. Case in point: the SU-122-54 and experimental Object 268 both had stereoscopic rangefinders installed on the commander's cupola as a technical requirement. However, Object 268 was deemed superfluous and the need for the SU-122-54 evaporated fairly quickly after it was accepted into service, not least because problems were encountered with the rangefinder. Optical rangefinders only found their way into Soviet tanks on a large scale with the advent of the T-64; the first tank to have an independently stabilized primary gunsight, and also the first tank to have an integrated optical coincidence rangefinder installed in said gunsight.

The left thumb button initiates turret traverse for target cuing, and the right thumb button turns the OU-3GK spotlight on or off, but the button must be held to keep the spotlight on. The spotlight should not be turned on for more than 20 seconds, as it will overheat without periodic cooling. A toggle switch on the race ring of the cupola enables the commander to keep the spotlight on or off. The range of elevation is +10° to -5°. The OU-3GK spotlight is mechanically linked to the TKN-3 by a pushrod to enable it to elevate and depress with the periscope.

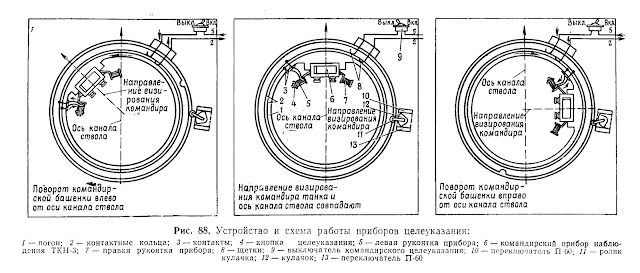

Target designating is done by placing the crosshair in the viewfinder of the TKN-2 or TKN-3 over the intended target and pressing the left thumb button, holding it until the turret is aligned with the periscope. It is theoretically possible to guide the turret if the commander keeps the left thumb button, hereby known as the target designator button, held down while turning his cupola. The system only accounts for the cupola's orientation, and not the periscope's elevation, so the the turret will traverse to meet the target, but the gun will not elevate to meet the commander's point of aim. This was not an issue, since the gunner needs to conduct the final lay on the target anyway. The wide field of view offered by the gunner's sight makes it practically impossible for the gunner to miss a target even if the turret was imperfectly aligned with the commander's periscope.

The target designation system is practically the same as the one used in the T-54. A direction sensor is installed at around the 3 o'clock position of the cupola, and has the function of determining the deflection of the TKN-3 relative to the longitudinal axis of the turret. The direction sensor consists of a roller placed in permanent contact with the cupola race ring, a cam attached to the roller and two switches. The roller is recessed into a notch in the cupola race ring when the cupola is turned to the 0 o'clock position relative to the turret - refer to the diagram in the middle.

When the cupola is turned to the right (see diagram on the right), the motion of the cupola race ring dislodges the roller from the notch and causes the roller to be deflected to the left by friction. The cam attached to the roller also rotates left, causing it to touch the switch on the right, but no action is taken until the target designator button is pressed. When the target designator button is pressed, an electric signal is sent from the button to the direction sensor via a conductor track on the cupola race ring. The depression of the right switch by the cam then triggers the turret rotation motor to turn the turret to the right until the roller returns to the notch, whereby the cam is no longer in contact with the right switch and no action is taken even if the commander keeps his thumb on the target designator button. The same mechanism is repeated in reverse when the cupola turns to the left. Since the direction sensor is composed of two switches which can only be either on or off, the command to initiate turret rotation is binary. This means that the turret is either turning, or it is not. For that reason, the turret always rotates at maximum speed when the target designation system is activated. This ensures that the gunner is cued to the target as quickly as possible. The the gun-laying precision of the turret at its maximum traverse speed is low, but that is irrelevant as the final lay is conducted by the gunner.

Because the cupola does not counter rotate as turret traverse is initiated, it may spin along with the turret as it rotates to meet the target cued by the commander, potentially causing him to lose his bearings. To prevent this, there is a simple U-shaped steel rung for him to brace with his right arm as he uses his left hand to designate the target. This wasn't as convenient as a counter rotating motor, of course, but it was better than nothing. The photo below shows the steel rung, as well as the toggle switch for the cupola's electrical systems (turns on power to TKN-3 and OU-3GK) next to the right part of the steel rung. The direction sensor is visible next to the left part of the steel ring.

Overall, the commander's observation equipment and facilities saw a minor improvement over the T-54B and T-55, but overall it was not better than on tanks like the Leopard 1 or Chieftain. The target detection capabilities of a T-62 commander were significantly worse at very long ranges (exceeding 3 km) owing to the limitations of the 5x magnification of the TKN-2 or TKN-3, compared to the 6-20x magnification of the TRP-5 of the Leopard 1 or the 10x magnification of the No.37 periscope of the Chieftain. However, it is important to keep in mind that independent American, German and Polish studies and field exercises have shown that in Central Europe, there is hardly any open terrain wide enough for a line of sight to extend further than 2 km. In Western Europe, the maximum line of sight permitted by the terrain is even shorter.

Sometime during the 1970's, a select number of tanks received a dust shield over the commander's hatch. It is a sheet steel face shield with a canvas skirt draping down. Being so thin, the dust shield is not bulletproof.

Nnot many T-62s received the addition though almost all T-72s did. The reason for this is unclear.

A T-55 gunner will find himself in familiar territory upon sitting on the gunner's seat in a T-62. The gunner's thickly padded seat is not adjustable in height but it can be folded flush against the U-5TS gun recoil guard to enable both the gunner and commander to move to the driver's compartment or exit through the escape hatch in the tank belly, which is behind the driver's seat. The turret of the T-62 does not have a turret basket with a safety cage to isolate the turret crew from the hull, but the gunner has a footrest. As an alternative, the gunner could simply rest his feet on the the rotating floor, which may have to be done to free up space for the gunner to use the manual elevation and traverse handwheels without bumping his hands on his knees. In general, the gunner is in little danger of getting his feet caught on something in the hull as he is normally in control of turret traverse. Overall, the gunner's station is quite spartan - other than these features, there is no other furniture.

Overall, the gunner's station is very well laid out and quite satisfactory in terms of ergonomics. Although it is still somewhat confining, it was not inferior to tanks like the Centurion and M60(A1) which had uncomfortable gunners' stations with small dimensions despite the tanks dwarfing the T-62 in external dimensions. In the report "Human Factors Engineering Evaluation of the M60 Main Battle Tank", it was detailed that "The gunner's working area ... is very restrictive and extremely uncomfortable even for a short period of time". Moreover, it was recommended in the report that "The seat could be suspended from the side of the basket and designed to fold down and out of the way for easy access to and from the gunner's position" - a feature that the M60(A1) lacked but was present in the T-62.

For extra visibility, the gunner has a single TNP-165 periscope pointed forward. The field of view from the periscope is 70 degrees. This periscope gives the gunner some additional awareness of the immediate area in front of the turret which can be important as the gunner is responsible for preventing the gun barrel from knocking into obstacles or digging into the ground. However, the TNP-165 for the gunner is more of a bonus than a necessity since the gunner's telescopic sight is installed on the same level as the axis of the gun barrel, so it is not difficult for him to see and control the gun to avoid damage. Rather, the TNP-165 periscope may be more useful for allowing the tank to be used more effectively in a turret-down position thanks to its high location on the turret roof. Having a telescopic primary sight mounted on the same level as the gun barrel means that the gunner cannot aim over the crest of a berm or hill when the tank is parked behind it, but by having a periscope on the turret roof just in front of the commander's cupola, the gunner is essentially given the same elevated view as the commander when the tank is in a turret-down position. The commander can use the target designation function of his TKN-3 optic when he sees a target, and the turret will be automatically traversed to face it and the gunner will be able to see it through the forward-facing TNP-165. After the gunner confirms visual contact with the target, he can look through his telescopic sight and wait until the commander gives the order for the driver to move forward. When the muzzle of the gun clears the crest of the berm or hill in front of the tank, the gunner can immediately acquire the target through his sight and open fire.

The periscope is also useful when the tank is not in combat as it gives the gunner some spatial awareness. Considering that the gunner does not have a hatch of his own, he is essentially stuck in his corner of the turret for the duration of any march which can quickly become tiresome.

In addition to all of the necessary switches and toggle buttons to activate this and that, there are also some other odds and ends at his station, including a turret azimuth indicator, which is used to orient the turret for indirect fire. It is akin to a clock, having two hands - the hour hand for general indication measured in 6000 mils, and the minute hand in 100 mil increments for precise turret traverse. Combined with the gunner's quadrant, the T-62 can conduct indirect fire.

The azimuth indicator has an internal bulb that can be turned on to allow the gunner to read it at night.

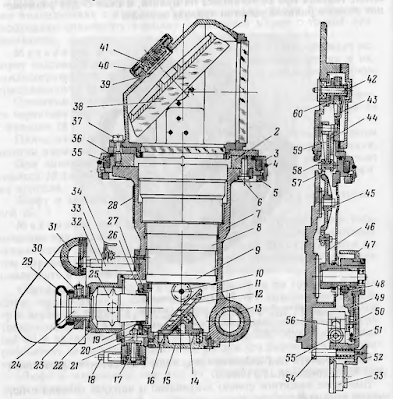

The gunner is provided with either a monocular TSh2B-41 articulated telescopic primary sight and a TPN1-41-11 night sight. Because the sight aperture is just left of the gun barrel, there is a very high likelihood that it will be rendered inoperable if the turret takes a hit around the cutout for the sight aperture. A non-perforating hit on the cutout may create a big enough shock to knock the sight out of alignment or even crack the lenses, not to mention the disastrous effects of a direct hit on the aperture itself.

In terms of technological sophistication, the fire control system of the T-62 was fundamentally equivalent to the T-54B which was a tank from 1957. The fact that the TSh2B-41 sight itself was essentially a product belonging in the late 1940's was entirely inconsequential because there was no real advancement in this field anywhere in the world. On its own, the TSh2B series of articulated telescopic sights was excellent in terms of quality and interfaced well with the "Meteor" stabilizer of the T-62. Rather, the main issue that should be focused on is that the T-62 lacked an optical rangefinder of high accuracy such as those found on American tanks like the M48A2C (1956) and M60 (1959), which was the main shortcoming of earlier Soviet tanks. This is one shortcoming that it shared with tanks like the Centurion. The emphasis that is often placed on American tanks having a ballistic computer is rather misguided as the focus should really be on the lack of an optical rangefinder rather than the lack of a ballistic computer.

On the M48A2 and M60A1, the M13A1D ballistic computer was necessary to interpret the data from the optical rangefinder into a useful form. When the fire control system is operating normally, the range data from the measurement made by the commander is entered into the computer by the turning of the rangefinder coincidence adjustment dial to generate a firing solution based on the ammunition type entered by the gunner. If the rangefinder is not used or it is not working, another method of entering range data is to use a small manual range crank on the side of the computer housing, and if the gunner notices that the shots are missing the target, he can input small range corrections by turning a toothed knob next to the range indicator dial.

The main point in understanding this is so that it becomes completely clear that the M13A1D ballistic computer only accepts two inputs and generates one output: it accepts range and ammunition type data and generates sight superelevation data. It is not at the same level as a modern ballistic computer that generates a nuanced output using a much larger number of variables including crosswind speed, ambient temperature, atmospheric pressure, propellant charge temperature, gun bore wear level, and so on. In other words, the M13A1D ballistic computer fundamentally fulfills the same function as the range scales in any day sight. The only advantage of having the ballistic computer was that it handled range data more precisely than a human gunner could achieve by scrolling a range scale up and down against a fixed horizontal line, but due to the law of diminishing returns, the actual effect that this advantage had on the accuracy of fire was very limited when put in the context of the high velocity ammunition that had become standard by the 1960's.

In practice, the lack of an optical rangefinder in the T-62 did not stop it from outmatching M60A1 tanks largely thanks to the use of high velocity APFSDS ammunition, but also partly because of the large size of the M60A1 itself. Furthermore, a T-62 gunner could be expected to have a quicker target acquisition and reaction speed thanks to the presence of a gun stabilizer and the dependent stabilization of the TSh2B sight. Without a stabilizer of any sort, it was impossible for an M60A1 gunner to effectively scan the tank's surroundings when in motion and the time needed to prepare the first shot when firing on a short halt was much slower than a T-62. A detailed examination of this topic will be provided later in the section on the "Meteor" series of stabilizer of the T-62. For now, the gun sights and their relationship with the fire control system of the T-62 will be explored.

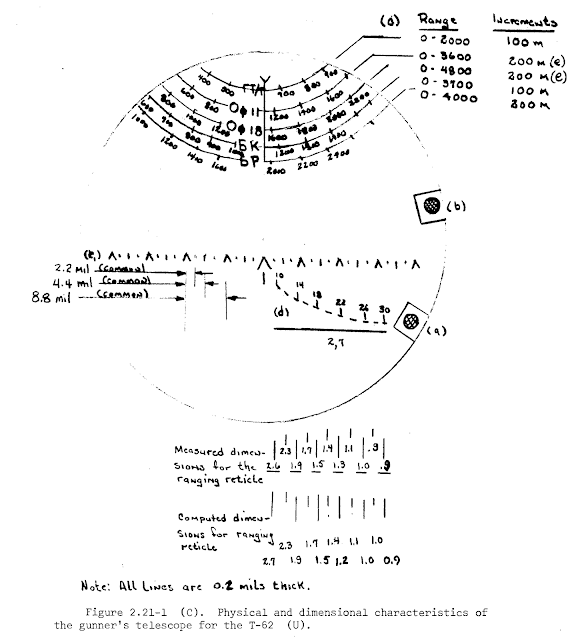

The TSh2B-41 is a monocular telescopic sight that functions as the gunner's primary sight for direct fire purposes. It has two magnification settings, 3.5x or 7x, and an angular field of view of 18° in the former setting and 9° in the latter setting. The magnification switch is located on top of the telescope housing. The TSh2B-41 also comes with a small wiper on the aperture window to clean off moisture and dust, and it comes with an integrated heater for defrosting. The sight has an internal light bulb that when turned on, illuminates the reticle for easier aiming in poor lighting conditions such as during twilight hours or dawn.

Slat armour screens - which were not a part of the original T-62M modernization package - also made their debut in Afghanistan. Such screens were installed at local bases and were highly valued because of the proliferation of handheld grenade launchers among Mujahideen fighters.

The details of such tanks will be explored later in this article.

Today, the T-62 is perhaps the least remembered among large number of tanks deployed by the Soviet Union during the Cold War. Its predecessor, the T-54/55, is known for being the so-called "Kalashnikov of tanks", having seen action in virtually every major military conflict on the planet during the past half century. Its successor, the T-72, has a similar level of fame for having participated in almost as many conflicts and in being the most mass-produced main battle tank. The T-62, on the other hand, lies in an indeterminate gray area. It is usually sidelined as an oddity, sometimes accused of being a failure, and sometimes (bizarrely) criticized for having a smoothbore gun. In the West, the T-62 is best remembered by those who served in NATO armies in the 1973-1980 time frame, especially those stationed in West Germany. Publicly available TRADOC documents and training films show that the U.S Army emphasized the T-62 as a foil to their own M60A1, which was apt considering that that was the political motivation behind the creation of the T-62. When more information on the T-64 and T-72 became available in the early to mid 1980's, all attention was shifted towards these two models and lesson plans focused on training soldiers to defeat an enemy tank that had composite armour.

Tactically speaking, there was practically no difference between it and its predecessor the T-55 in the mobility and armour protection departments, and the T-62 also shared most of its internal equipment with the T-55, thus simplifying both production and logistics to a certain extent. Even many of the newer devices were functionally similar, making the transition from a T-54 or T-55 to the T-62 wonderfully seamless for the crew. In fact, it is stated in a 1981 Soviet essay titled "Из Опыта Совершенствования Основных Танков В Ходе Серийного Производства" that 65% of the parts and assemblies in the T-62 were standardized with the T-55 tank. Most interestingly, the transmission, chassis, engine assembly, viewing devices and communication systems were completely interchangeable between the two contemporary tanks. Operationally, this made it extremely simple to supply spare parts and carry out repairs in the field. The non-interchangeable components such as the turret and hull are irrelevant as these items would never require a replacement. Rather, if a tank were knocked out by having its armour breached, it is much more likely to be salvaged for spare parts to support other tanks rather than be repaired, as that is much more expedient in actual wartime conditions.

Being a mere evolutionary stepping stone, we can observe the way Soviet school of thought on mechanized warfare evolved with it. In the early 60's, tank riding infantry was still considered a core part of mechanized warfare. The armoured APC had arrived on the scene in the form of the wheeled BTR-152 and tracked BTR-50, but infantry were sometimes obliged to move and fight as one with a tank as they could effectively provide protection from enemy anti-tank teams equipped with grenade launchers, and so to that end, the T-62 had handrails over the circumference of the turret for tank riders to hold on to. When the BMP-1 was introduced in 1966, it drove a major revision of contemporary tank tactics, and the shift in paradigm can be very well seen in the T-62's successors. The T-64A did not have any handrails, nor did the T-72, and the T-62M introduced in the 80's abolished them too.

The changes to the T-62 dutifully followed international trends as well, most notably the global shift to jet power in the aviation industry. Too fast to be harmed by machine gun fire, the ground attack jet rendered the normally obligatory 12.7mm anti-aircraft machine gun obsolete. During the late 1950's and early 1960's, anti-aircraft machine guns were thus omitted from medium tanks but remained on heavy tanks like the T-10M, partly because the KPVT on the T-10M offered more firepower than the smaller caliber DShKM on medium tanks. Even the usefulness of a 12.7mm machine gun on ground targets was not persuasive enough to justify the retention of anti-aircraft machine guns to Soviet specialists at the GBTU (Main Directorate of Armoured Forces). The T-55, T-55A and T-62 were all affected by this new policy. The heavy use of helicopters for fire support and landing missions during the American war in Vietnam created a need for tanks to be armed with a large caliber anti-aircraft machine gun, and this was further emphasized by the appearance of dedicated attack helicopters or gunships like the AH-1 "Huey Cobra". The first T-62 tanks armed with a DShKM in an anti-aircraft mount appeared in 1969, and this modification became standard for new-production tanks beginning in May 1970. Older tanks were also retrofitted at the factory when they were brought in for their scheduled overhauls.

The first pre-production models of the T-62 appeared in 1961. In the Soviet Union, the T-62 was mass-produced from 1962 to 1975, making it the direct contemporary of NATO tanks like the M60A1, Leopard 1 and Chieftain which appeared in 1962, 1965 and 1966 respectively. After 1975, all "new" T-62s are actually simply upgraded, modified, or otherwise overhauled versions from the original production run. By then, production at the No. 183 factory had irreversibly shifted to T-72 production.

Like the M60A1, Leopard 1 and Chieftain, the T-62 was a completely different tank than its predecessor, but unlike these three foreign tanks, it did not represent a major change in mobility or protection. Technically speaking, the only difference was in its firepower. Nevertheless, the inherently good tactical-technical characteristics of the basic T-54 were so good and the original design was so solid that the T-62 could still be considered an equal among these main battle tanks.

Table of Contents

- Ergonomics

- Ventilation

- Commander's Station

- TKN-2 "Karmin"

- TKN-3 "Kristal"

- Gunner's Station

- TSh2B-41, TSh2B-41U

- TShS-41U

- TShSD-41U

- TPN1-41-11

- Volna Fire Control System

- TShSM-41U

- 1K13-2 Sight

- Loader's Station

- Ammunition Stowage

- Rate of Fire

- U-5TS (2A20) Gun

- Stabilizer

- Auto-ejector

- Ammunition

- HE-Frag

- APFSDS

- HEAT

- Secondary Weapon

- Tertiary Weapon

- Protection

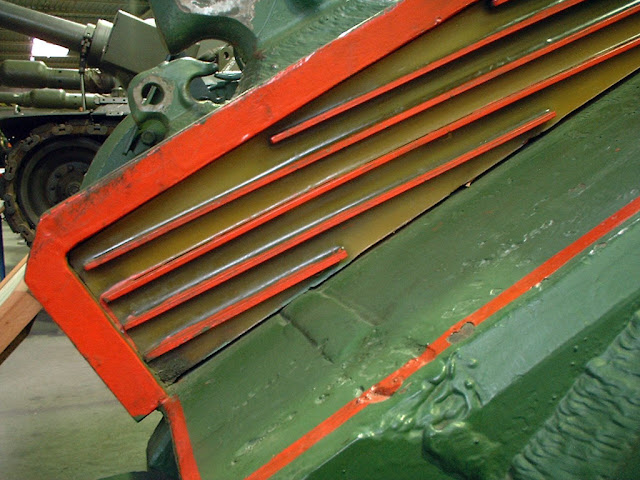

- Side Skirts

- Yom Kippur

- Ilyich's Eyebrows

- Belly Armour

- Slat Armour

- Kontakt-1

- Mine Clearance

- NBC Protection (PAZ)

- Smokescreen

- Fire Fighting

- Driver-Mechanic's Station

- Mobility

- Suspension

- Engine Deck

- Road Endurance

- Water Obstacles

ERGONOMICS

The widened turret ring did not directly affect the width of the hull, but the length of the fighting compartment had to be increased by a small amount (386mm) in order to accommodate its increased diameter. The arrangement of the roadwheels and the torsion bar suspension was also revised in accordance with the redistribution of weight towards the nose of the hull, thus removing the distinctive gap between the first and second roadwheels on the T-54 and T-55 that is often used as an identification feature. Instead, the T-62 suspension has its three front roadwheels densely packed together, with larger gaps between the last two roadwheels. The combat weight of the tank was increased by one ton to 37 tons, but of this weight, less than 400 kg can be attributed to the weight difference between the 115mm U-5TS and the D10-T2S. The remainder is from the new hull and turret. Contrary to expectations, the T-62 was actually slightly lighter than the T-55A, which weighed 37.5 tons combat loaded.

However, that was not the entire extent of the changes made to the hull and chassis. Compared to the T-54/55, the maximum height of the hull was increased from 977mm to 1,036mm and the maximum internal height of the fighting compartment (from the rotating turret floor to the turret ceiling) went up very slightly from 1,600mm to 1,610mm. Due to the mildly sloping roof of the hull, the actual internal height differs at varying points across its length. Moreover, the suspension of the T-62 was fundamentally identical to the T-54 suspension, but it incorporated small improvements such as an increased ground clearance of 471.5mm instead of 440mm and it provided a somewhat smoother ride. Externally, at first glance, it seems that the T-62 is both wider and taller the T-54/55 by a few inches but surprisingly, the height of the T-62 up to its turret roof almost did not change at all compared to the T-54 - it increased only negligibly from 2,235mm to 2,248mm. Like the T-54, the total height of the tank up to the top of the commander's cupola is 2,400mm.

The internal volume of a T-62 was larger compared to a T-54 or T-55 chiefly due to the need to accommodate the bigger gun, but due to the increase in the turret ring diameter and the rearrangement of the internal equipment in the tank, it was possible to allocate more room to the crew. Although the T-62 superficially resembles the T-54 from many angles, the dome-shaped turret was larger and noticeably more spacious, even with the larger cannon. This can be largely attributed to the 2,245mm diameter turret ring, which was not only a big improvement over the 1,825mm ring of the T-54, but it was even quite cavernous compared to foreign tanks. The photo below, provided courtesy of Chris "Toadman" Hughes, shows a stripped-out T-62 hull.

The turret ring of the T-62 was much wider than the one on the Leopard 1 (1,980mm) and still somewhat wider than that of the M48 and M60 which had the widest turret ring (2,160mm) among all Western tanks in service at the time, later shared by the Chieftain. This was only partially offset by the larger cannon breech housing of the U-5TS gun compared to the 90mm medium velocity guns of most M48 models, but when measured across the recoil guards, the U-5TS was actually narrower than the 20 pdr. and the L7.

Technically, the immense diameter of the T-62 turret ring was far in excess of the necessary size to handle the recoil of the 115mm gun. For example, the T-10M heavy tank which had a considerably more powerful 122mm gun could manage with a smaller turret ring of 2,160mm and even the later main battle tanks such as the T-64A and T-72 had a smaller 1,934mm turret ring despite having an even more powerful 125mm gun, thanks to the use of a two-man turret. While certainly beneficial in terms of reducing the intensity of stresses induced by the moment of force from the recoil of the gun, the large size of the T-62 turret ring was primarily designed for ergonomic purposes. It was a carryover from the earlier Object 140 medium tank project which featured the 100mm D-54TS gun, as the large working space granted by the large turret ring was necessary to allow the long and unwieldy 100mm cartridges to be handled by the loader, according to a description given by Chief Designer Leonid Kartsev in his memoirs. The turret ring diameter was left unchanged after the 115mm gun was created and fitted, leaving the tank with a surplus of space.

The large turret ring provided some additional working space for the crew along the axis of the hull, though this was still limited by the ammunition racks placed at the front and back of the hull. Because of this, the effective increase in fighting compartment length was less than the difference in turret ring diameter between the T-62 and the T-54/55 (420mm). Rather, it merely corresponded to the increase in the hull length of 386mm. This can be seen in the photo below, taken from a West German report on a captured T-62 tank delivered by Israel. Additionally, it is important to note that it was not possible for the increased turret ring diameter to translate directly into an increase in seating space between the commander and gunner, because in virtually all turreted tanks, the need for the turret to rotate in a full circle means that the maximum seating space is governed by the clearance provided in the hull. This is not only evident from the hull width being smaller than the turret ring diameter, but it can also be seen in the fact that both the front and rear hull ammunition racks intrude into the turret ring perimeter. As such, the commander and gunner seats in a T-62 turret only gained a modest amount of space apart from each other, not as large as the turret ring alone suggests. The added width directly provided by the turret ring only begins at hip level for a standing crew member, considering that useful internal height of the hull at the fighting compartment is just over 950mm.

The wide turret ring granted the possibility of upgunning the T-62 without requiring serious turret modifications and without bringing repercussions to the working conditions of the crew, unlike the T-54 which was unsuitable for a gun larger than the D10T. In fact, this possibility was demonstrated by the Object 167 experimental tank which was built using the Object 166 turret and featured a 125mm D-81T gun complete with an assisted (semi-automatic) loading system.

In terms of shape, the turret of the T-62 dispensed with the egg-shaped curvature of the T-54 turret in favour of an ostensibly simpler yet more sophisticated hemispherical turret. This contributed to a modest increase in the amount of habitable room inside the turret, mainly for the loader. The difference in the turret shapes can be seen in the two drawings below, with the T-62 on the left and the T-54 on the right.

Interestingly enough, the T-62 turret is among the few conventional tank turret designs with its gun bore axis aligned with its centerline while having all crew members seated within the turret ring perimeter, giving both halves of the turret a symmetrical amount of space. Due to its enormous width, there was no need to have the gun installed with an offset toward the loader's station to free up more room for the gunner, commander and their equipment. Virtually all other turret designs with this layout solved the issue of insufficient space for the commander and gunner by providing the commander with a protruding cupola and seating him above the level of the turret ring, rather than within it. Other solutions include the omission of a third crew member, or the relocation of the commander from a tandem seating space with the gunner to an isolated seat behind the main gun. In general, alignment of the gun bore axis to the centerline of the turret is beneficial to the recoil reaction dynamics of the weapon system, as the recoil axis is aligned to the center of rotation of the turret. Thus, no excess torque is generated during the firing of a shot to turn the turret. This reduces the stress on the turret traverse mechanism and marginally reduces the total horizontal error in the point of aim.

One factor that partially counterbalances the overwhelmingly larger size of the T-62's turret ring compared to the T-54 or T-55 is the design of the turret ring itself. On the T-62, the walls of the turret rest on top of the ball bearing race ring of the turret ring in the same way as the turret of the Centurion tank whereas on the T-54/55, the walls of the turret are in front of the turret ring. The implications of this design decision on the protection level of the turret will be explored later in the "Protection" section of this article, but for now, the impact on the actual space available inside the turret is a more interesting topic to examine.

Because of the difference in the turret ring design, the T-54/55 turret has a relatively deep shelf between the turret ring and the wall of the turret along the rear half of its circumference. This creates additional space for internal equipment such as the radio transceiver and its power supply unit, the communications control boxes of both the commander and gunner, and so on. The T-62 turret has a much more shallow shelf that is only deep enough for smaller pieces of equipment like the communications control box. The radio transceiver had to be installed next to the gunner's seat, making the gunner's station narrower than the turret ring diameter implies, and a new turret traverse lock mechanism that protruded inwards of the turret ring was used. However, the overwhelmingly larger turret ring diameter of the T-62 still provides a net positive to the amount of crew space available.

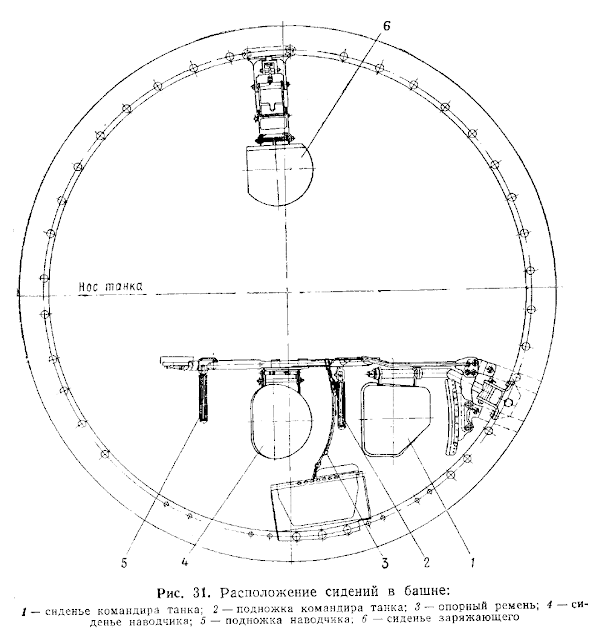

Having a larger turret ring than the M48 and M60 did not mean that the T-62 was comparatively more spacious, as the hulls of the two aforementioned tanks were still wider. The M48 and M60 both had turret baskets which were mounted to the turret ring, thus giving a direct correlation between turret ring diameter and crew compartment diameter. For both the Leopard 1 and M48 or M60, the turret basket mount occupies some space and reduces the diameter of the crew compartment by a few centimeters. It would be safe to assume that the diameter of the crew compartment is approximately 1,900mm for the Leopard 1 and approximately 2,040mm for the M48 and M60 (due to hull width constraints). On the other hand, the T-62 lacks a turret basket so the width of the crew compartment is determined entirely by the internal width of the hull, which is 1,850mm. This is almost the same as a Leopard 1 but significantly less than the M48 and M60. On the other hand, the exceptionally large turret ring and correspondingly wide turret grants more room above the waistline. The length of the crew compartment is also larger, but even so, the commander and gunner in the T-62 are still seated rather closely, albeit much further apart than in a T-54 or T-55. This can be seen not only in the physical gap between the seats, but also in the position of the commander's footrest; in a T-54 or T-55, the commander's footrest was beneath the gunner's seat cushion, not behind it. The main improvement is seen in the loader's station, who also benefited from the relocation of several pieces of equipment. The seating arrangement in the T-62 turret is shown in the drawing below.

One factor that partially counterbalances the overwhelmingly larger size of the T-62's turret ring compared to the T-54 or T-55 is the design of the turret ring itself. On the T-62, the walls of the turret rest on top of the ball bearing race ring of the turret ring in the same way as the turret of the Centurion tank whereas on the T-54/55, the walls of the turret are in front of the turret ring. The implications of this design decision on the protection level of the turret will be explored later in the "Protection" section of this article, but for now, the impact on the actual space available inside the turret is a more interesting topic to examine.

Because of the difference in the turret ring design, the T-54/55 turret has a relatively deep shelf between the turret ring and the wall of the turret along the rear half of its circumference. This creates additional space for internal equipment such as the radio transceiver and its power supply unit, the communications control boxes of both the commander and gunner, and so on. The T-62 turret has a much more shallow shelf that is only deep enough for smaller pieces of equipment like the communications control box. The radio transceiver had to be installed next to the gunner's seat, making the gunner's station narrower than the turret ring diameter implies, and a new turret traverse lock mechanism that protruded inwards of the turret ring was used. However, the overwhelmingly larger turret ring diameter of the T-62 still provides a net positive to the amount of crew space available.

Having a larger turret ring than the M48 and M60 did not mean that the T-62 was comparatively more spacious, as the hulls of the two aforementioned tanks were still wider. The M48 and M60 both had turret baskets which were mounted to the turret ring, thus giving a direct correlation between turret ring diameter and crew compartment diameter. For both the Leopard 1 and M48 or M60, the turret basket mount occupies some space and reduces the diameter of the crew compartment by a few centimeters. It would be safe to assume that the diameter of the crew compartment is approximately 1,900mm for the Leopard 1 and approximately 2,040mm for the M48 and M60 (due to hull width constraints). On the other hand, the T-62 lacks a turret basket so the width of the crew compartment is determined entirely by the internal width of the hull, which is 1,850mm. This is almost the same as a Leopard 1 but significantly less than the M48 and M60. On the other hand, the exceptionally large turret ring and correspondingly wide turret grants more room above the waistline. The length of the crew compartment is also larger, but even so, the commander and gunner in the T-62 are still seated rather closely, albeit much further apart than in a T-54 or T-55. This can be seen not only in the physical gap between the seats, but also in the position of the commander's footrest; in a T-54 or T-55, the commander's footrest was beneath the gunner's seat cushion, not behind it. The main improvement is seen in the loader's station, who also benefited from the relocation of several pieces of equipment. The seating arrangement in the T-62 turret is shown in the drawing below.

Although the gain in space between the commander and gunner compared to a T-54 or T-55 was fundamentally constrained by the hull width, the greatly increased diameter of the turret ring still made a large difference as it permitted the commander to sit with his legs straight forward when his feet were placed on the footrest, and no longer straddling the gunner's back. The gunner could use the commander's knees as a backrest or choose to use his leather backrest which would be stretched from the recoil guard on the gunner's right and hooked to the turret ring on his left. The details of the gunner's seating station will be discussed at a later point. The seating situation can be seen in the image below.

In this aspect, the T-62 is on par with the Leopard 1, which is far from surprising given that they share almost the same hull width. The photo on the left below shows the interior of a Leopard 1, demonstrating the close similarity in working space in both tanks with the commander's recoil guards removed in both images. Even the Chieftain, shown on the right below, does not provide significantly more space between the gunner and commander despite the large size of the tank.

For comparison, the gunner in a T-54 had to have his back straddled by the commander when leaning into his backrest or sit in a slouching posture, which eventually leads to back aches if continued over a prolonged period. The alternative of having the commander place his knees around the gunner's back is also not ideal, because of the lack of space to move freely. In actual operational terms, this has tangible downsides, such as restricting movement when both crewmen are wearing winter clothing, or more seriously, hindering the commander and gunner while they are donning NBC protection equipment during a sudden chemical attack (which cannot be handled by the anti-nuclear protection system). The latter was not a consideration in legacy tank design concepts during WWII, which was inherited by the T-54. In this sense, the additional space provided in the T-62 was not merely a luxury, but had real tactical merits.